What is a Process Flowsheet

Process flowsheet can simply be defined as a blue print of a plant or part of it. It identifies all feed streams, unit operations, streams that inter-connect the unit operations and finally the product streams. Operating conditions and other technical details are included depending on the detail level of the flowsheet. The level can vary from a rough sketch to a very detailed design specification of a complex plant.

Aspen Exchanger Design & Rating 4. Aspen Economic Evaluation 5. Aspen Basic Engineering Asset Performance Management Interoperability The aspenONE Asset Performance Management Suite includes four products (listed below). It is recommended that when more than one of these products are used on the same computer,. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features Press Copyright Contact us Creators. Oct 14, 2019 Description. Aspen Plus V10 User Models Manual. This manual is intended for the Aspen Plus user who wants to create custom Fortran subroutines and CAPE-OPEN modules to extend the modeling capabilities of Aspen Plus. Prior programming experience with Fortran, C or Visual Basic is recommended.

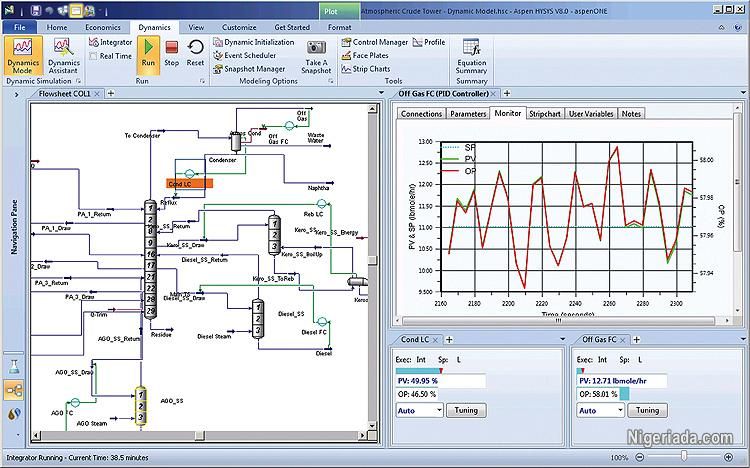

For steady-state operation, any process flowsheet leads to a finite set of algebraic equations. For a case where we have only one reactor with appropriate feed and product streams the number of equations may be manageable by manual hand-calculations or simple computer applications. However, as the complexity of a flowsheet increases and when distillation columns, heat exchangers, absorbers with many purge and recycle streams come into the picture the number of equations easily approach many ten thousands. In these cases, solving the set of algebraic equations becomes a challenge in itself. However, there are computer applications called process flowsheet simulators specialized in solving these kinds of large equation sets. Some well known process flowsheet simulators are Aspen Plus™, ChemCad™ and PRO/II™. These products have highly refined user interfaces and on-line component databases. They are used in real world applications from interpreting laboratory scale data to monitoring a full scale plant.

Advantages of using a process flowsheet simulator

The use of a process flowsheet simulator is beneficial in all the three stages of a plant: research & development, design and production. In research & development they help to cut down on laboratory experiments and pilot plant runs. In design stage they enable a speedier development with simpler comparisons of various alternatives. Finally, in the production stage they can be used for risk-free analysis of various what-if scenarios.

Aspen Plus Download

Disadvantages of using a process flowsheet simulator

Manual solution of a problem usually forces someone to think deeper on the problem, find novel approaches to solve it, and evaluate and reevaluate the assumptions closer. A drawback of process flowsheet simulators may be cited as the lack of this detailed interaction with the problem. This might act as a double edged sword. On one side it hides the complexities of a problem so you can concentrate on the real issues at hand. On the other side this hiding may also hide some important understanding of the problem as well.

History

In 1970s the researchers at MIT's Energy Laboratory developed a prototype for process simulation. They called it Advanced System for Process Engineering (ASPEN). This software has been commercialized in 1980's by the foundation of a company named AspenTech. AspenTech is now a publicly traded company that employs 1800 people worldwide and offers a complete integrated solution to chemical process industries.

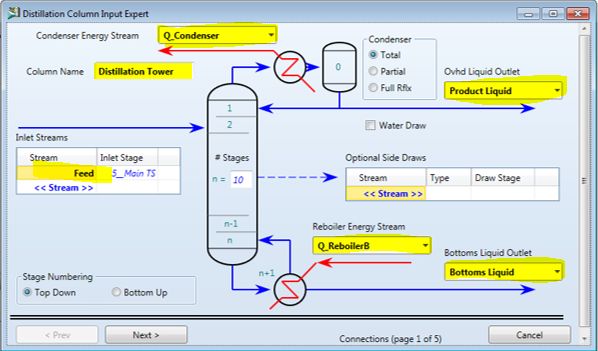

This sophisticated software package can be used in almost every aspect of process engineering from design stage to cost and profitability analysis. It has a built-in model library for distillation columns, separators, heat exchangers, reactors, etc. Custom or propriety models can extend its model library. These user models are created with Fortran subroutines or Excel worksheets and added to its model library. Using Visual Basic to add input forms for the user models makes them indistinguishable from the built-in ones. It has a built-in property databank for thermodynamic and physical parameters. During the calculation of the flow sheet any missing parameter can be estimated automatically by various group contribution methods.

In this workshop we will only scratch the surface of this tool. We will discuss its advantages and disadvantages. Our focus will be on reactors and our goal is to provide you with a smooth and simple introduction to Aspen Plus. Let's start our workshop by learning how to access Aspen Plus™ at The University of Michigan.

Aspen Plus™ at The University of Michigan

The current version supported by CAEN is 2006.5. Files generated in older versions are upward compatible and will be converted automatically to the newer version. Aspen Plus™ has an extensive on-line documentation library. All on-line documentation is available either as standard Windows help file or as PDF documents.

Aspen Plus™ can be invoked by following this path:

Aspen Plus Manual

From Programs menu find

Aspen Plus V10 Download

Engineering Applications -> Aspen Engineering Suite 2006.5 -> Aspen Plus 2006.5

And click

Aspen Plus User Interface